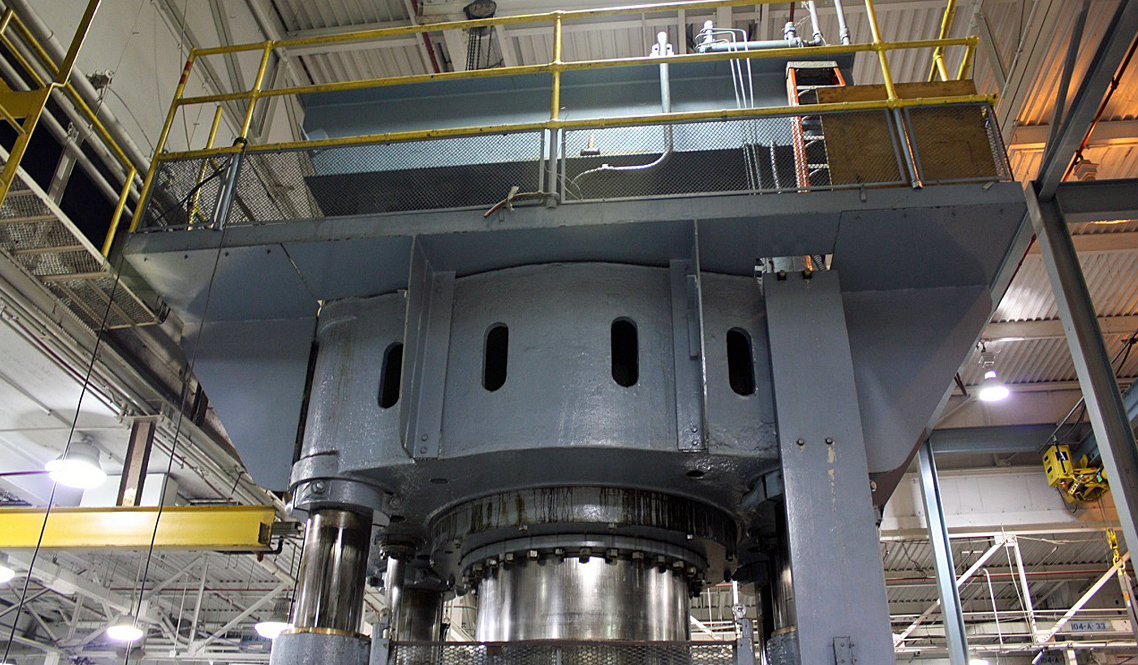

Due to all of the heavy maneuvers hydraulic presses have to undergo regularly, you may experience some problems associated with this machinery; here are some of the most common ones and how to fix and avoid them. You can also get the best hydraulic press repair service via https://www.macrodynepress.com/press-rebuilds-upgrades/.

Image Source: Google

Oil Leaks

A common frequently reported problem is leaky oil You will see oil in the ram, fittings for the hose's end, and the hydraulic lines. Make sure that you use the correct oil to your press, and make sure all fittings are secured.

Overheating

Intense friction and pressure as well as a degraded or contaminated hydraulic fluid could cause your machine to overheat. Hydraulic presses shouldn't exceed 150 degrees F because overheating could result in damage to sealing materials.

Slow Pressure Build-Up

Normally, the hydraulic press achieves the pressures required in a single second. anything more than that indicates there's an issue with the pump, or the fluid isn't getting directed to the ram enough.

It could be caused by the leak or the dirt that is trapped in the fluid. Therefore, be sure to inspect the pump along with the other mechanisms, like the relief valve or motor to ensure that everything is operating well and in good order.

Regular inspections and maintenance will extend the lifespan of the hydraulic presses; however, they will not guarantee its longevity. Be sure to take care of your technology to make the most of it!